continous casting

Rolling ingots and extrusion billets with solid or hollow cross section are manufactured in continuous or discontinuous, horizontal or vertical casting. The molten metal is stored in a tundish and flows from there through a tundish metering nozzle in an open watercooled ingot mold. It forms a frozen layer on the surface which allows to change the direction from vertical to horizontal. After that it cools down and get cut. The horizontal continuous casting is mainly used for small-format strands (like dental alloys, hard alloys, special alloys, copper alloys and other non-ferrous alloys).

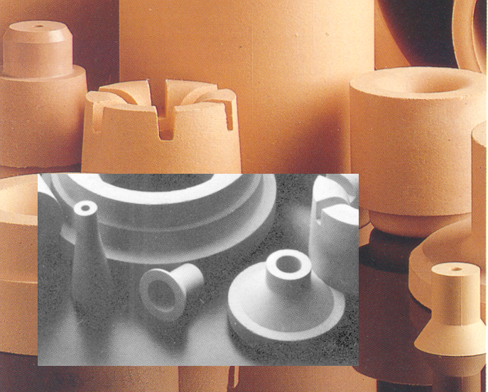

The tundish metering nozzles, nozzle inserts, slide gates and slide gate inserts are made out of zirconia and have to withstand temperatures of about 1,600 °C and massiv erosion.